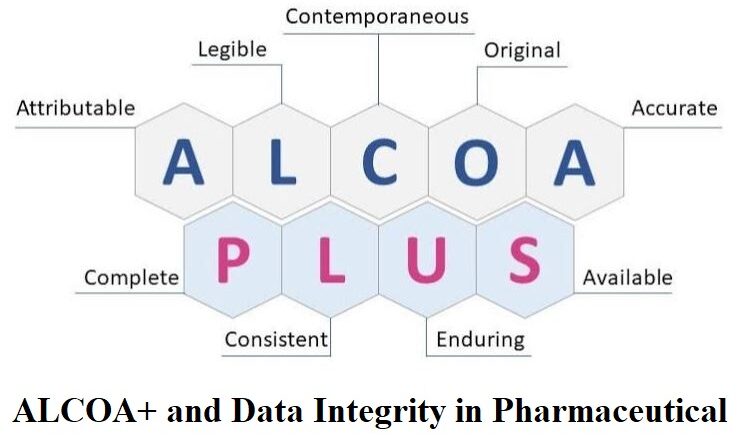

ALCOA+ and Data Integrity in Pharmaceutical

ALCOA+ and Data Integrity in Pharmaceutical is being discussed in this knowledgeable post. Basically, Alcoa is an acronym that stands for Attributable, Legible, Contemporary, Original, and Accurate. Later, Alcoa expanded to Alcoa Plus (Alcoa +), adding a few more concepts that are; Complete, consistent, durable, and available. In addition, the ALCOA + data integrity principles define best practice guidelines and methodologies for good data management, for example, in the pharmaceutical and biotechnology industries. The acronym "ALCOA" defines that the data must be attributable, legible, contemporary, original, and accurate. In addition, the "ALCOA +" guide recommends that the data also be complete, consistent, durable, and available.

With the passage of time, ALCOA+ and Data Integrity in ...