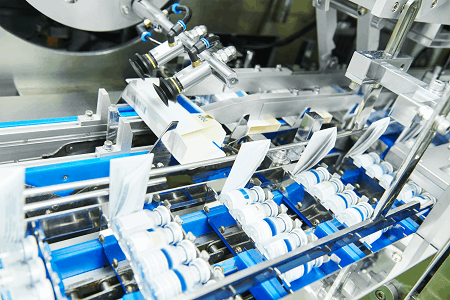

Packing of Products on a Packaging Line SOP

In this SOP the complete procedure of Packing of Products on a Packaging Line is described which is applied in the pharmaceuticals production section.

Packing of Products on a Packaging Line OBJECTIVE

1.1 To lay down the procedure for packing of a product on a packaging line.

SCOPE

2.1 The scope of this SOP applies to the procedure for packing of a product on packaging line in packaging section of production department.

3.0 RESPONSIBILITIES

3.1 It is the responsibility of Line Supervisor (packaging) to follow this SOP as it is written.

3.2 It is the responsibility of Packaging Pharmacist to ensure that this SOP is followed as it is written.

3.3 It is the responsibility of Production Manager to ensure that this SOP is followed in its entirety, reviewed and updated as necessa...