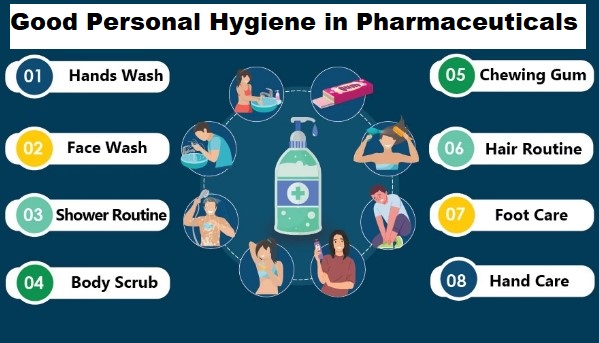

Good Personal Hygiene in Pharmaceuticals is required in the pharmaceutical industries to protect the product and avoid any contamination that affects the quality of the medicinal product. Good Personal Hygiene in Pharmaceuticals Individuals are responsible for the quality of medicinal products and may therefore be collectively referred to as “staff”.

Purpose:-

The purpose of this procedure is to prevent contamination of Products prepared at the Surge Plant by employees working or Vice Versa.

Scope Good Personal Hygiene in Pharmaceuticals:-

This procedure is applicable to all the Good Personal Hygiene in Pharmaceuticals working at, ……………..located

HSE Statement:-

N.A

Responsibility:-

Officer QC/QA in coordination with Manager QA/QMR will ensure that SOP has been successfully followed at Surge Plant.

Departmental Head ensures that all employees are following proper hygiene requirements when they report to work.

Materials:-

Below mentioned materials needed for the implementation of this procedure:-

- Personnel Protective Equipment as mentioned in SOP

Definitions:-

Personnel Hygiene:-

Personal hygiene involves properly caring for your body by keeping it clean and healthy while allowing you to look and feel your best.

“OR”

It is also a highly effective way for you to protect yourself from illness and infection.

Flow Chart

Chapter No. Flow Chart Description Responsibility

Personnel Cleaning

Arrive at work with neat & Clean cloth , Cut nails & with proper bath

Proper Clothing

Neat and clean fully covered cloth, use facility-issued apron (Lab coat / Overall) if required on site

Hair Restraints and Jewelry

With fully covered hair Neatly trimmed Beard & moustaches No jewellery & Cosmetics allowed with in the premises

Illness

In case of contaminated disease sent employee at home to prevent contamination

Cuts, Abrasions and Burns

Use proper bandages & Gloves

Smoking, eating, and gum chewing

Not allowed at Premises

- Arrive at work with neat & Clean cloth , Cut nails & with proper bath

- Neat and clean fully covered cloth, use facility-issued apron (Lab coat / Overall) if required on site

- With fully covered hair

- Neatly trimmed Beard & moustaches

- No jewellery & Cosmetics allowed with in the premises

In case of contaminated disease sent employee at home to prevent contamination

Use proper bandages & Gloves

- Not allowed at Premesis Departmental Head

- HR Department

- Manager QA/QMR

- Officer QA/QM

Procedure:-

Personnel Cleaning:-

- Arrive at work with clean hair, teeth brush & bath.

- Maintain short, clean, and polish-free fingernails. No artificial nails are permitted in production area.

- Wash hands (including under fingernails) and up to forearms vigorously and thoroughly with soap and warm water for a minimum of 20 seconds:

- When entering the facility before work begins.

- Immediately before handling equipments, Products & start of Manufacturing Process.

- As often as necessary Manufacturing Process when contamination occurs.

- In the restroom after toilet use and when you return to your work station.

- When switching between working.

- After touching face, nose, hair, or any other body part, and after sneezing or coughing.

- After cleaning duties.

- Between each task performed and before wearing disposable gloves with disinfectant.

- After eating, or drinking.

- Any other time an unsanitary task has been performed – i.e. taking out garbage, handling cleaning chemicals, wiping tables, picking up a dropped item.

- Wash hands only in hand sinks designed for that purpose.

- Dry hands through electric hot dryer.

Proper Clothing

- Wear appropriate clean uniform with sleeves and closed-toed work shoes that are comfortable for standing and working on floors that can be slippery.

- Wear facility-issued apron (Lab coat / Overall) if required on site:-

- Remove apron before using the restroom.

- Change apron if it becomes soiled or stained.

Good Personal Hygiene in Pharmaceuticals Wear disposable gloves with any cuts, sores, rashes, or lesions.

Hair Restraints, Jewelry & Cosmetics:

- Covered the hair in Production & Laboratory Area.

- Keep beards and moustaches neat and trimmed.

- Refrain from wearing jewelry in the production & Laboratory Area.

- Necklaces, Earrings, Bracelets, Dangling Jewelry, Wrist Watches & Cosmetics (Like nail Polish, Lipstick & Eye Lenses) are strictly prohibited in controlled areas.

Illness:

Report any flu-like symptoms, diarrhoea, and/or vomiting to the Department supervisor / Officer. Employees with these symptoms will be sent home with the exception of symptoms from a noninfectious condition; employees could be re-assigned to activities so that there is no risk of transmitting a disease.

Cuts, Abrasions, and Burns:

- Bandage any cut, abrasion, or burn that has broken the skin.

- Cover bandages on hands with gloves and change as appropriate.

- Inform your immediate manager of all wounds.

Smoking, eating, and gum chewing:

Smoking, eating, and gum chewing is not allowed with in the premises.

Records

Personnel Hygiene Inspection

References

- Journal of Validation technology [Autumn 2009] (Hand Washing—A Critical Aspect of Personnel Hygiene in Pharma)

- Sanitation & Personnel Hygiene – WHO Guidelines

Distribution:-

This SOP is distributed at below mentioned departments:-