In this post procedure of operation Of Paste Cooking Kettle is describe as given below

Operation Of Paste Cooking Kettle OBJECTIVE

1.1 To describe procedures for the operation of Steam Jacket Kettle.

SCOPE

2.1 This SOP applies to the operational procedure of Steam Jacket Kettle.

RESPONSIBILITIES

3.1 It is the responsibility of steam jacket kettle Supervisor (Liquid manufacturing) to follow this SOP as it is written.

3.2 It is the responsibility of Production Pharmacist (Oral Liquids), to ensure that this SOP is followed as it is written.

3.3 It is the responsibility of Senior Production Manager to make certain that this SOP is followed in its entirety, review and update as necessary.

DEFINITIONS& ABBREVIATIONS

NA

MATERIALS & EQUIPMENTS

NA

PROCEDURE

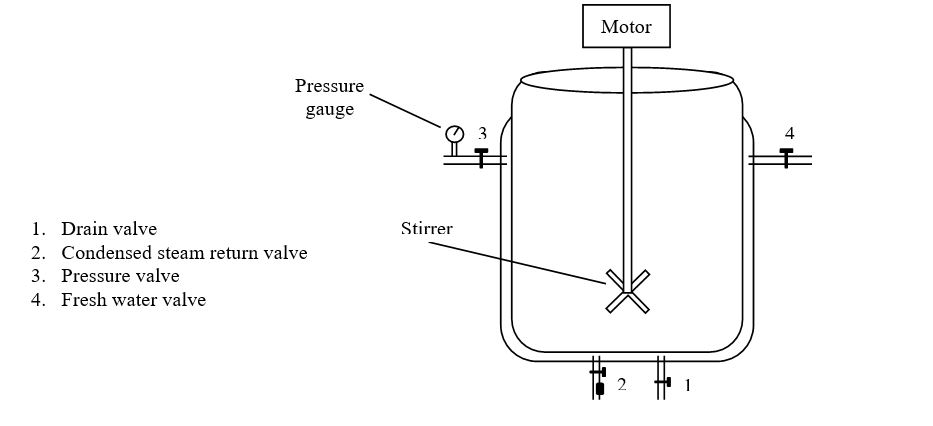

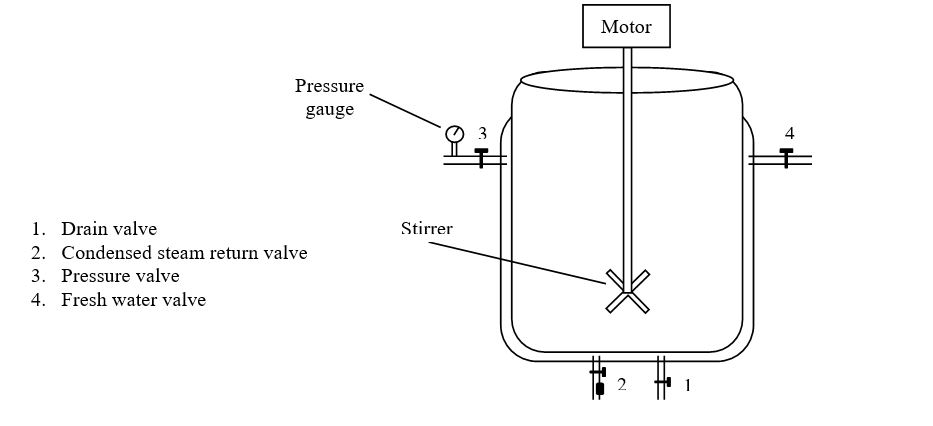

6.1 Open the drain valve (1) to remove the water from the jacket. Close the drain valve and fill the jacket with fresh water.

6.2 Plug in the electric supply of the kettle and switch “ON” the electric supply.

6.3 Fill the kettle with required quantity of De-Ionized water for paste preparation.

6.4 Set the digital thermostat meter according to the required temperature, and start the heater of the kettle.

6.5 Separately dissolve the maize starch in cooled water and stirrer it continuously to avoid the lumps formation.

6.6 After the water starts boiling in the kettle, add the starch at once and start the mixer to mix the starch with hot water.

6.7 A semi sold transparent starch paste will be formed , continue the mixing process until a homogeneous translucent starch paste is formed.

6.8 Turn “OFF” the electric heater and mixing rotar of the kettle.

6.9 Open the discharge valve of the kettle and remove the paste from the kettle in suitable S.S. container.