A Standard Operating Procedure SOP for Operation of Autoclave Use in Pharmaceutical Industry is crucial to ensure the proper sterilization of equipment, materials, and products. Here’s an example SOP outline for the operation of an autoclave.

This example SOP serves as a general guideline. Adjustments should be made to align with the specific equipment and procedures within your pharmaceutical facility. Regular review and updates to SOPs are necessary to ensure compliance with current industry standards and regulations.

PURPOSE

To lay down a procedure for the operation of steam sterilizer (Autoclave). The objective of this SOP is to outline the proper procedures for the safe and effective operation of the autoclave to achieve sterilization of equipment, materials, and products in compliance with industry standards and regulatory requirements.

SCOPE

This SOP is applicable for the operation of an autoclave (Hirayama, HVE-50) used for sterilization of heat-resistant materials in the microbiology lab of the Pharmaceuticals Site-2.

RESPONSIBILITIES & AUTHORITIES

- Microbiologists are responsible for the operation of autoclave for the sterilization of equipment and material as per SOP.

- Microbiology Head is responsible for the preparation and implementation of this SOP as well as for the operation of steam sterilizer as per SOP.

- Quality Control Manager is responsible to review the SOP.

- Quality Assurance Manager is responsible to approve the SOP.

- Director Operations is responsible for the final authorization and implementation of the SOP.

DEFINITIONS & ABBREVIATIONS

Sterilization

Sterilization refers to any process that kills all forms of life (especially microorganisms such as fungi, bacteria, spores, and unicellular eukaryotic organisms) and other biological agents such as prions from a specific surface, object, or in or on it. Removes, kills or disables existing fluid

Steam Sterilization

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time period.

Autoclave

An autoclave is a machine that uses pressurized steam to kill harmful bacteria, viruses, fungi, and spores that are placed inside a pressurized vessel.

N.A – Not Applicable

SOP – Standard Operating Procedure

PROCEDURE

SOP for Operation of Autoclave Use in Pharmaceutical Industry

Setting Up the Operation

Following steps are to be followed for a complete sterilization cycle in an autoclave (Hiclave HVE-50).

Power On

- Press the power ON/OFF switch at the front of the body

- When the open/close Lever is set to “LOCK” which means the position of the lever is left side, mode number is indicated on the display. The display indication changes to setting values after 2 seconds and the autoclave is ready in this state.

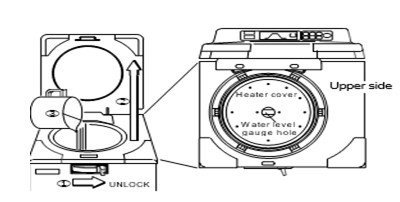

- When the Open/close lever is set to “UNLOCK” lid and temperature in the working chamber are shown on the display as below

- In operation of UNLOCK/LOCK lever, never fail to put POWER switch ON.

- Pouring Water into Vessel

- Slide the open/close lever to unlock the door (right end)

- Lift the lid by grabbing the handle as shown in figure-2.

- Pour water in chamber until you can see water through the hole at the center of the heater cover.

- Maximum quantity of water for Hi clave HVE-50 is 2.0 liters.

- Do not Pour anything expect water

- Raise the lid slowly for opening. This will reduce the fear of damaging the lid because of impact created.

Loading of the Substance

- Load the substance to be sterilized into the chamber

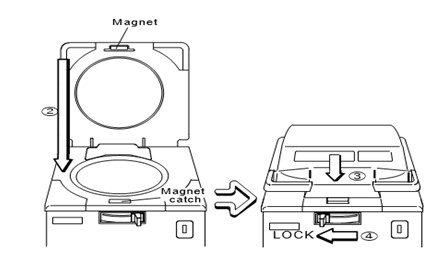

- Raise down the lid by holding handles

- Press the front centered position until the magnet catch gets attracted to the magnet.

After magnet catch attachment, move the open/close lever to left end to lock the chamber

- Keep the lid open for 15 minutes or more between operations when the equipment is operated continuously. Check that the temperature in the working chamber is 50°C or less before starting the next operation.

- Be sure to use the Heater cover.

Selection of Mode (Process)

Following mode are programmed in this system. Select an appropriate one.

Press the MODE switch

- Each time the switch is pressed, the current mode repeatedly changes from Mode 1 to Mode 2, 3, 1… In sequence.

- Setting values are displayed after 2 seconds of mode number indication.

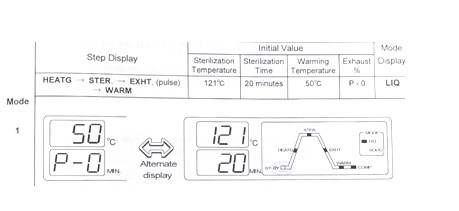

- Mode-1: Sterilization of agar medium

Figure: 5

Figure: 5

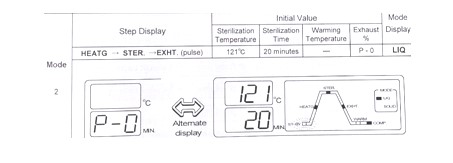

Mode-2: Sterilization of liquids such as water, media, reagents and liquid medicines that withstand high temperature and pressure.

Mode-3: Sterilization of tools of glass, ceramic, metal or rubber that withstand high pressure and temperature.

Changing Set Values

- Press the SET/ENT switch

- The display of the set sterilization (dissolution) temperature will flash indicating that the value is now changeable

- Press the NEXT switch to select an item to change

- Change the displayed value by setting increase/decrease switches

- Each time the switch is pressed the displayed values are increased/decreased as follows

Sterilization Temperature: (In increments of 1ºC within a range of 😉

HVE-50: 105~135ºC

Sterilization time: 1-minute increments within a range of 1-250 minutes.

Warming Temperature: 1ºC increments within a range of 45-80ºC - If a switch is held down, the displayed values are decreased/increased by 10 units increment.

- Press the SET/ENT switch

- The change value is stored and display stopped blinking and lights up. This completes the setting Operation.

Starting of the Operation

- Starting of the autoclave

- Make sure that the water level in the exhaust bottle is between HIGH and LOW levels.

- Make sure that the water level in the drain bottle is low enough not to touch the tip of the exhaust hose.

- Confirm that the fine exhaust knob is closed.

- Press the START/STOP switch

- The open/close lever is locked and lid cannot be opened.

- Thereafter, one of the processes will be executed depending upon the selected mode.

Unloading

- Confirm that the gauge for pressure in chamber reads “0 MPa”

- Slide the open/close lever to unlock (right side)

- Lift the lid by holding handles

- Take the sterilized material out of the chamber.

After Completion of Operation

- Turn off the POWER switch after the completion of each routine operation.

- If the exhaust knob is open, turn it until closed.

- To prevent the clogging of piping & rusting of heater, change the water of the chamber once a day.

Cancellation of Operation

- Press the START/STOP switch

- The process being executed will be interrupted and the equipment will return to the standby state.

Power Break Down During Operation

- If power supply is shut off before the completion of the operation due to power failure, operation is interrupted and the power switch is in the off state when power supply comes back.

Draining of the Chamber

- Open the lid.

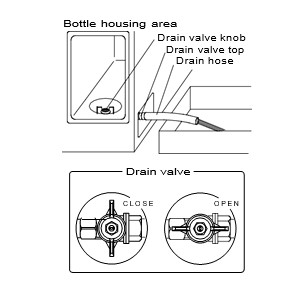

- Connect one end of the attached drain hose to the tap of the drain valve located at the lower part of the right side of the body.

- Put the other end of the hose in a container.

- Remove the exhaust bottle from the body.

- Turn the drain valve knob, located at the bottom of the exhaust bottle housing area, counterclockwise to open.

- Check if draining of the chamber is complete.

- Turn the knob clockwise to close the drain valve. Be sure the exhaust valve is closed.

Figure-15

Figure-15

Precautions

- Never connect the power cord to a power supply other than one of the rated voltages. Connection to such a power supply can cause fire or electric shock.

- Do not use the autoclave for the purpose other than sterilization and agar preparation (dissolution)

- Do not pour anything except for water.

- Be careful not to pinch your hands when closing the lid.

- The lid, chamber, gasket and panel are extremely hot immediately after the completion of operation. Do not touch the equipment or you may get burned.

- Do not put your face or hands close to the chamber when lifting the lid after operations are complete; steam will gush out of the chamber.

- Do not forcibly bend, twist, tie or extend the power cord. Do not place heavy objects on the cord. A damaged cord or exposed wire can cause fire or electric shock.

Cleaning of the Equipment

- Take out the bottom plate to see if the bottom of the chamber or the surface of the heater is dirty.

- After draining the chamber, clean these areas with a soft brush or other tool while applying water and keeping the drain valve open.

- If the temperature sensor comes loose from the fixing clip, reattach it.

- Gently wipe stains from the body with a soft cloth.

- To remove stubborn stains, wring a cloth moistened with neutral detergent diluted with water, and wipe off the stains with it. Wipe off any moisture with a dry cloth.

Note: After using the equipment, following information will be noted in the autoclave sterilization cycle record (FQC-MI-016)

- Date

- Items name

- Temperature

- Pressure

- Temperature achieving time

- End time

- Autoclave Strip

- Performed by

- Verified by

AMENDMENT/ CHANGE STATUS

| AMENDMENT STATUS | |||||

| Sr.# | Date of Amendment | Page No | Issue Status | Effective Date | Details of change / review |

| 1 | |||||

| 2 | |||||

| 3 | |||||

RELATED DOCUMENTS

Autoclave Sterilization Cycle Record

REFERENCES & ATTACHED DOCUMENTS

Manufacturer’s Manual (Hiclave HVE-50)

USP <1211> Sterilization & Sterility Assurance of Compendial Articles

DISTRIBUTION LIST:

| Distribution | Copy No. | Received by(Signature/ Date) | Withdrawn on(Signature/ Date) |

| Quality Assurance | Master | ||

| Quality Control | 01 |

ANNEXURES

Autoclave Sterilization Cycle Record.