Calibration is one of the most frequently used techniques in pharmaceutical analysis. This involves measuring the amount of ultraviolet radiation or seen absorbed by a substance in the solution. The calibration instrument measures the ratio, or function ratio, from the intensity of two light beams in Qualitative UV analysis, organic compounds can be identified using spectrophotometers, if there are recorded data available, and quantitative spectrophotometric analysis is used to ensure the quantity of molecular species that absorb radiation. Calibration of spectrophotometric techniques are simple, fast, quite specific and applies to small quantities of compounds. Fundamental law that regulates calibration spectrophotometrically analysis

PURPOSE:

To describe the Calibration procedure for the operation of the UV / Vis spectrophotometer.

SCOPE:

This SOP provides a detailed outline for the operation of UV / vis spectrophotometer and will include Calibration procedures of equipment.

RESPONSIBILITY:

QC analyst is responsible for calibration equipment and preparing standard operating procedures.

It is the responsibility of the QC Manager to help and ensure the calibration procedure according to the SOP and to ensure that this SOP is followed overall, regularly reviewed and revised as needed.

REFERENCE:

In-house specifications

Material and Equipment:

UV / vis spectrophotometer

PROCEDURE:

CALIBRATION:

- Operate the instrument as per SOP.

- Calibration of UV/VIS Spectrophotometer is done in five steps.

- Control of wavelength.

- Control of absorbance.

- Limit of stray light.

- Resolution power.

- Wavelength accuracy, resolution & baseline flatness (inbuilt test).

Control of wavelength:

- Weigh accurately 1.0g of Holmium oxide and dissolve it in 1.4M Perchloric acid solution. Make up to 25.0ml with the same solvent.

- Select the method file of CONTROL OF WAVELENGTH in the instrument.

- After selecting the file press reference button for baseline correction.

- Then fill the cuvette with 1.4M Perchloric acid and put in the sample cubicle and press reference to zero.

- After auto zero put the Holmium perchlorate solution in sample cubicle then press start key.

- Scan it and verify the wavelength using absorption maxima of holmium perchlorate solution. The permitted tolerance is given.

- The permitted tolerance is ±1nm for UV range and ±3nm for visible range.

- Observed the wavelength and tolerance is given in Sop.

Control of absorbance:

Dry a quantity of the potassium dichromate by heating to constant weight at 130oC.

Solution A:

- Weigh accurately about 57.0-63.0mg of dried potassium dichromate, suppose 60.0mg will be taken.

- Dissolve it in 0.005M sulphuric acid solution.

- Make up to 1000.0ml with the same solvent.

- Mark the solution as A, by using black marker.

- Solution B:

- Weigh accurately about 57.0-63.0mg of dried potassium dichromate, suppose 60.0mg will be taken.

- Dissolve it in 0.005M sulphuric acid solution.

- Make up to 100.0ml with the same solvent.

- Mark the solution as B, by using black marker.

- Select the method file of CONTROL OF ABSORBANCE in the instrument.

- After selecting the file press reference button for baseline correction.

- Then fill the cuvette with 0.005M sulphuric acid for blank and put in both sample cubicle and press reference to zero.

- After auto zero put the potassium dichromate solution labeled as solution ‘A’ in sample cubicle, then press start key taking absorbance individually for first four λ mentioned in annexure-2.

- Now take absorbance at 430.0nm for solution ‘B’.

- Note the absorption maxima of potassium dichromate solution at different wavelength.

- Calculate the absorbance; tolerance is given in Sop.

Limit of stray light:

- Dry a quantity of the potassium chloride by heating to constant weight at 130oC.

- Weigh accurately 1.20g of dried potassium chloride and dissolve it in 50.0ml of purified water.

- Make up to 100.0ml with the same solvent.

- Select the method file of LIMIT OF STRAY LIGHT in the instrument.

- After selecting the file press reference button for baseline correction.

- Measure absorbance of the above solution at 198.0, 199.0, 200.0, 201.0 & 202.0nm using water as blank.

Acceptance criteria:

Absorbance is greater than 2.0.

Resolution power:

- Prepare 0.02% v/v solution of toluene in hexane.

- Dissolve 0.02ml of toluene in sufficient hexane and make up to 100.0ml by using same solvent.

- Record the spectrum in the range of 260.0nm to 420.0nm. (Before use of above solution, check hexane for

- transmittance using water as a blank between 260.0nm to 420.0nm & use only if transmittance is not less than 97%). Select the method file of RESOLUTION POWER in the instrument.

- After selecting the file press reference button for baseline correction.

- Measure absorbance of the above solution at 266nm and 269nm using hexane as blank solution.

- The ratio of absorbance maxima at 269nm to that of 266nm minima can be calculated as:

- Ratio= Absorbance at 269nm

- Absorbance at 266nm

Acceptance criteria:

The ratio of absorbance maxima at 269nm to that of 266nm minima should be more than 1.5.

Wavelength accuracy, resolution & baseline flatness (inbuilt test):

- Attach printer directly to the instrument (instead of computer).

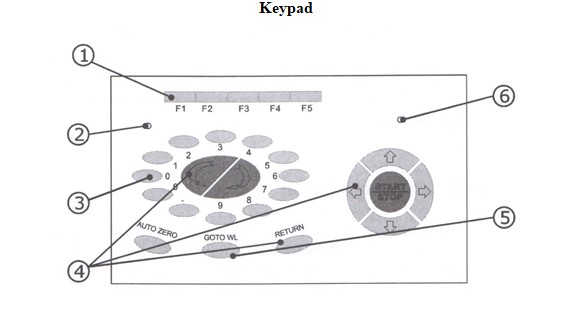

- Go to Ϸ MODE press F3 key i.e. Maintenance.

- Press ‘1’.

- Press start/stop key.

- After screen changes, ensure that nothing is kept in the optical path & press start/stop key again.

- Print will come after all the three tests are over.

Acceptance criteria:

- For wavelength accuracy:

- At 656.1±0.3nm.

- At 486.0±0.3nm.

Resolution: - 1.0nm or less.

- Baseline flatness:

- ±0.002 Abs.

Frequency:

Once in a month.

Maintenance/ repairs:

- When the instrument does not comply with the requirement/ tolerance range specified above, the instrument should be labeled “OUT OF CALIBRATION” and should be repaired/ serviced.

- After repair/ maintenance, calibrate the instrument.

- Note down the report in the internal calibration certificate and in instrument logbook.