Air Changes and Product Data Analysis

Air Changes and Product Data Analysis uses in Pharmaceuticals is the use and application of data analytics in the pharmaceutical industry. Integrating big data analytics solutions into pharmaceutical manufacturing processes allows companies to gain valuable insights to accelerate and optimize production.

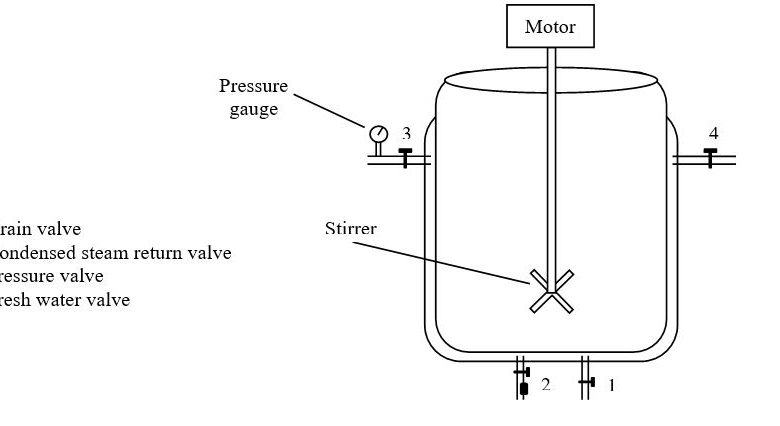

Standard operating procedure Air Changes and Product Data Analysis to measure the air velocity and air changes per hour in CFM in classified area. The measured air quantity shall not be less than the designed air quantity and the calculated air changes shall not be less than the designed air changes per hour.

Objective :-

To ensure the air changes in sterile areas (clean Room) as per specification and To analyses product related data for conformance to specifications, determ...