In the pharmaceutical industry, the proper control of temperature and air quality is essential for ensuring the quality, safety, and efficacy of products. Classification of HVAC Systems in Pharmaceuticals (heating, ventilation, and air conditioning) systems play a crucial role in maintaining the required conditions for pharmaceutical manufacturing, storage, and distribution. The HVAC system helps to maintain cleanroom conditions, regulate temperature and humidity levels, and provide fresh and filtered air.

Pharmaceutical facilities often require a high level of control over environmental conditions to meet regulatory requirements, prevent contamination, and ensure product stability. The Classification of HVAC Systems in Pharmaceuticals is a critical component of the overall environmental control system and must be designed and maintained to meet the specific needs of the facility.

HVAC systems can be classified into several categories based on the type of system, the method of air distribution, and the level of control and automation. Some of the most common Classification of HVAC Systems in Pharmaceuticals are:

Central Classification of HVAC Systems in Pharmaceuticals

Central HVAC systems are designed to provide heating and cooling for an entire building or facility. They consist of several components, including an air handling unit, a furnace, a condenser, an evaporator, and a refrigerant system. Central HVAC systems are the most complex and sophisticated type of HVAC system and are typically more expensive and require more maintenance than other types of HVAC systems.

The main advantage of central HVAC systems is that they provide consistent heating and cooling throughout an entire building or facility, which can help to maintain a consistent and comfortable indoor environment. Additionally, central HVAC systems can be more energy efficient than other types of HVAC systems, as they are able to optimize the heating and cooling of an entire building or facility.

Split Systems:

Split systems are made up of two separate components: an outdoor unit and an indoor unit. The outdoor unit contains the compressor and condenser, while the indoor unit contains the evaporator. Split systems are typically used in smaller buildings or facilities, or in specific rooms or spaces where the use of a central Classification of HVAC Systems in Pharmaceuticals is not feasible.

The main advantage of split systems is that they are relatively simple and inexpensive to install and maintain, compared to central HVAC systems. Additionally, split systems can provide efficient heating and cooling for specific rooms or spaces, which can help to maintain a comfortable indoor environment in those areas.

Package Systems:

Package systems are self-contained units that provide both heating and cooling for a single room or small space. They typically consist of an air handling unit, a furnace, and a refrigerant system. Package systems are relatively simple and inexpensive compared to central HVAC systems, and are typically used in smaller buildings or facilities, or in specific rooms or spaces where the use of a central HVAC system is not feasible.

The main advantage of package systems is that they are simple and inexpensive to install and maintain and can provide efficient heating and cooling for specific rooms or spaces. Additionally, package systems can be more energy efficient than other types of HVAC systems, as they are designed to optimize the heating and cooling of a specific room or space.

Hybrid Systems:

Hybrid systems are a combination of central and split HVAC systems and provide the benefits of both types of systems. Hybrid systems typically consist of a central HVAC system, with additional split systems installed in specific rooms or spaces where additional heating and cooling is needed.

The main advantage of hybrid systems is that they provide the consistency and energy efficiency of central HVAC systems, while also allowing for the flexibility and efficiency of split systems in specific rooms or spaces. Additionally, hybrid systems can be more cost-effective than other types of HVAC systems, as they allow for a balance between the cost and efficiency of central and split systems.

Ducted Systems:

Ducted systems use air ducts to distribute conditioned air throughout a building or facility. Ducted systems can be central, split, or package systems, and are typically used in larger buildings or facilities, or in buildings or facilities where the use of air ducts is feasible.

The main advantage of ducted systems is that they provide consistent heating and cooling throughout a building or facility, which can help to maintain a comfortable indoor environment. Additionally, ducted systems can be more energy efficient than other types of HVAC systems, as they allow for the optimization of heating and cooling throughout an entire building or facility.

Ductless Systems:

Ductless systems use individual air handling units, rather than air ducts,

to distribute conditioned air throughout a building or facility. Ductless systems are typically split systems and consist of an outdoor unit and multiple indoor units.

The main advantage of ductless systems is that they are more flexible than ducted systems, as they allow for the heating and cooling of specific rooms or spaces without the need for air ducts. Additionally, ductless systems can be more energy efficient than other types of HVAC systems, as they allow for the optimization of heating and cooling for specific rooms or spaces.

Another advantage of ductless systems is that they are relatively simple and inexpensive to install, compared to ducted systems. They are also typically more discreet, as the indoor units can be mounted on walls or ceilings, and do not require the use of air ducts, which can be visually obtrusive.

In summary, there are several different types of HVAC systems, each with its own advantages and disadvantages. When selecting an HVAC system for a building or facility, it is important to consider factors such as size, cost, energy efficiency, and the specific heating and cooling needs of the building or facility. A professional HVAC contractor can help you determine the best type of HVAC system for your needs and can provide guidance on installation and maintenance.

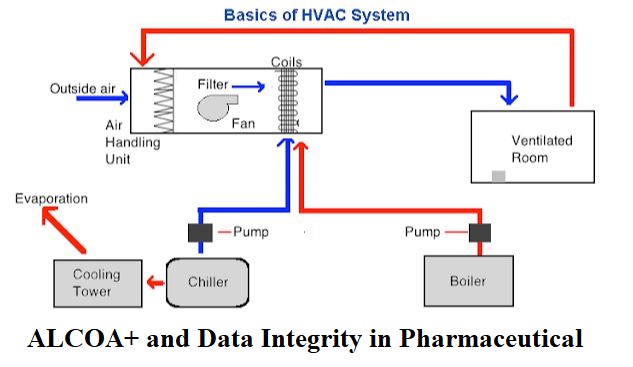

Parts of a Classification of HVAC Systems in Pharmaceuticals

The components of an HVAC (Heating, Ventilation, and Air Conditioning) system typically include:

- Air Handling Unit (AHU): The AHU is responsible for filtering, heating, and cooling the air before it is distributed throughout the building or facility.

- Ductwork: This is a network of pipes and vents that distribute conditioned air throughout the building or facility.

- Blowers and Fans: These components help to circulate air within the HVAC system and distribute it throughout the building or facility.

- Heating and Cooling Coils: The heating and cooling coils are responsible for warming or cooling the air that is being distributed throughout the building or facility.

- Thermostats: Thermostats control the temperature of the building or facility by sending signals to the HVAC system to turn on or off.

- Refrigerant Lines: The refrigerant lines are responsible for transporting refrigerant from the outdoor unit of a split system to the indoor unit, where it is used to cool or heat the air.

- Evaporator and Condenser Units: The evaporator and condenser units are responsible for removing heat from the air in the building or facility, and for expelling it to the outside.

- Electrical and Control Systems: The electrical and control systems are responsible for controlling the operation of the HVAC system and for ensuring that it runs smoothly and efficiently.