Tapentadol, a centrally acting opioid analgesic, is used in the treatment of moderate to severe acute and chronic pain, as well as the management of neuropathic pain associated with diabetic peripheral neuropathy in adults (extended release formulation only). How to Test Tapentadol Hydrochloride Tapentadol functions as an opiate agonist by binding to mu-opioid receptors and inhibiting norepinephrine reuptake. Approximately 97% of the parent drug is metabolised. The main route of tapentadol metabolism is conjugation with glucuronic acid to produce glucuronides. Tapentadol and its metabolites (N-desmethyltapentadol and hydroxyl-tapentadol) are excreted almost entirely through the kidneys, with the conjugated form accounting for approximately 70% of the drug excreted in urine. Tapentadol metabolites do not have analgesic activity. How to Test Tapentadol Hydrochloride Tapentadol has a half-life of 4 hours.

Description:

White to off white crystalline powder.

Procedure: Take 2 gms of the sample in a watch glass and observe the sample visually against a black background.

Solubility :

Soluble in methanol

- Descriptive test for solubility

- Soluble in methanol ( 1 gm in 10 ml to 30 ml of methanol)

Identification :

a) By IR: IR Spectrum of the sample should concordant with that of the working standard.

Procedure: Mix 1 part of subs in 300 parts of KBr, prepare a palate, and record the spectrum of the sample from 4000cm-1 to 400cm-1, taking air as reference.

Loss on drying :

Not more than 0.5%

Procedure: Weigh accurately about lgm of test sample and transfer it to the weighing bottle of weight (W1 ) with stopper, previously dried at 100-105°C for 30rnin. cool the weighing bottle at RT in desiccators. Note down the weight of the bottle with the spl. (W2) Distribute the sample evenly in the bottle. Place the weighing bottle uncovered at 100°C in an oven for 3 hours. After 3hrs, open the oven and immediately place the stopper on the weighing bottle. Place the weighing bottle in dessicator to RT. Determine weight of the weighing bottle with the contents. Note down the weight (W3).

Calculation:

(W2-W3) x 100

% Loss on drying = —————————-

(W 2-W 1 ).

Heavy metals :

Not more than 10 m

Lead Nitrate stock solution:

Procedure: Dissolve 159.8 mg of lead nitrate in 100 ml of water to which has been added 1 ml of nitric acid, then dilute with water to 1000 ml. Prepare and store this solution in glass container free from soluble lead salts.

Standard lead solution :

On the day of use dilute 10 ml of lead nitrate stock solution with water to 100 ml. Each ml of standard Lead solution contains the equivalent of 10 µg of lead. A comparison solution prepare on the basis of 100 micro liter of standard lead solution per gm of substance being tested contains the equivalent of 1 part of lead per million parts of substance being tested.

pH 3.5 Acetate Buffer- Prepare as directed as follow;

Dissolve 25. 0 gm of ammonium acetate in 25 ml of water & add 38. ml of 6 Normal hydrochloric acid. Adjust if necessary with 6 Normal Ammonium Hydroxide or 6 Normal Hydrochloric Acid to pH of 3.5, Dilute with 100 ml. & mix.

Standard Preparation:

In to 50 ml colour comparison tube pipette 2 ml, of standard stock solution 20 µ of Pb) & Dilute with water to 25 ml. using a pH meter or short range pH indicator paper as external indicator, Adjust with 1 Normal Acetic acid Or 6 Normal ammonium Hydroxide to pH between 3.0 to 4.0 dilute with water to 40 ml. & mix.

Test Preparation: Use a quantity in gm of the substance to be tested as calculated by the formula,

2.0 I (l000L)

In which, L is the heavy metals limit in percentage. Transfer the weighed quantity of the substance to a suitable Crucible add sufficient sulfuric acid to wet the substance & carefully ignite at low temperature until thoroughly charred (The crucible may be loosely covered with a suitable lid during the charring) add to the carbonized mass 2 ml. of nitric acid & 5 drops of sulfuric acid & heat cautiously until white fumes no longer are evolved. Ignite Preferably in a muffle furnace at 500° C to 600° C Until the carbon is completely burned off Cool add 4 ml. of 6 Normal of Hydrochloric Acid , Cover Digest on a steam bath for 15 min. , Uncover and Slowly evaporated on the steam bath to dryness. Moist the residue with 1 drop of hydrochloric acid & add 10 ml of hot water & digest for 2 min.Add 6 Normal ammonium hydroxide drop wise until the solution is just alkaline to litmus paper Dilute with water to 25 ml. & adjust with 1 Normal Acetic acid to pH between 3 to 4 Using short range pH indicator paper as an external indicator. Filter if necessary Rinse the crucible & the filter with 10 ml of water, Combine the filtrate & rinsing in a 50 ml Colour – comparison tube, Dilute with water to 40 ml. & mix.

Procedure: To each of the tubes containing the standard preparation & Test preparation add 2 ml.of pH 3.5 Acetate Buffer then add 1.2 ml of thioacetamide – glycerine base TS, Dilute with water to 50 ml. mix Allow to stand for 2 Min & view downward over a white surface: the colour of the solution from test preparation is not darker than that of the solution from the standard re aration.

0ptical rotation :

Between -22.0° to -28.0°

Procedure: Weigh and dissolve 0.9 gm of the sample in methanol and dilute to 100 ml with same solvent. Measure the specific optical rotation at 589 nm.

Melting Point:

Between 198c_ 203c

Procedure: Start melting point apparatus, until the temperature is about 10 °C below the expected melting temperature Introduce the filled capillary into the melting point apparatus Continue the heating, with constant stirring, sufficiently to cause the temperature to rise at the rate of about 1 °C per minute. Continue the heating and note the temperature at which the column of the sample collapses definitely against the side of the tube at any point, when melting may be considered to have begun and note also the temperature at which the sample becomes liquid throughout as seen by the formation of a definite meniscus. The two-temperature fall within the limits of melting range.

Test solution preparation: Weigh and transfer 10 mg ofTapentadol Hydrochloride Sample in 10 ml volumetric flask, dissolve in 1 ml of ethanol and dilute up to mark with mobile phase.

Standard solution preparation: Weigh and transfer 10 mg of Tapentadol Hydrochloride standard in 10 ml volumetric flask, dissolve in 1 ml of ethanol and dilute up to mark with mobile phase.

System suitability solution

Weigh and transfer 10 mg of Tapentadol (2R,3R-isomer) and 5 mg (2R,3S-isomer) in 10 ml of volumetric

flask, dissolve in 1 ml of ethanol and dilute up to mark with mobile phase.

System suitability criteria: Theoretical Plate Not Less than 2000.

Procedure:

Inject blank followed by system suitability solution, standard solution and test solution.

Data Reporting:

Disregard the peaks due to blank and Calculate Isomer in the test sample by area normalization method. Approximate retention time and relative retention time for components are given in following table.

| Component | ( Approximate )Retention Time min)(RT) | Relative retention time (RRT) |

| 2R,3S-isomer | 14.98 minutes | 0.80 |

| 2R,3R-isomer | 18.61 minutes | 1.00 |

Related substances by HPLC: * 3-NP-09 impurity : Not more than0.15%

Single Impurity : Not more than 0.5 % Total Impurities : Not more than 1.0 %

Chromatographic conditions :

| Column | Inertsil C18, 4.6 X 250 mm, 5µm. |

| Wavelength | 219 nm |

| Flow rate | 1 ml/min |

| Mobile phase | Buffer : Methanol; 48 : 52 ( v/v). Preparation of buffer solution : 5.7 gm/lit Ammonium phosphate in water, adjust pH 6.3 with triethylamine |

| Diluent | Mobile phase |

| Injection volume | 10 µl |

Preparation of solutions :

Preparation of system suitability: Dissolve 5 mg of 3NP-09 standard and 25 mg of tapentadol hydrochloride standard in 50 ml of volumetric flask and make up with diluent.

Sample preparation: Dissolve and dilute 50 mg of tapentadol hydrochloride san1ple in 50 ml of volumetric flask , make up with diluent.

Standard preparation: Dissolve and dilute 50 mg of tapentadol hydrochloride standard in 50 ml of volumetric flask, make up with diluent.

Order of injection:

| Blank | 1 |

| SST solution | 1 |

| Blank | 1 |

| Standard solution | 1 |

| Sample solution | 2 |

Procedure: Inject sample as per injection order into the chromatogram and calculate the impurities by area normalization method.

Assay by potentiometric :

Between 98.00 to 102.00 % (ODB)

Procedure: Weigh accurately 0.2 gm of the sample and dissolve in a mixture of 20 ml of glacial acetic acid and 20 ml of acetic anhydride and titrate against 0.1 N Perchloric acid.

Each 1 ml of 0.1 N Perchloric acid is equivalent to 25.78 mg of Tapentadol hydrochloride.

Calculation :

Burette reading x Normality of Perchloric acid x 25.78 x 100 x 100

% Assay by potentiometric – ———————————————————————————————

Weight of sample x (100 – % loss on drying)

Assay by HPLC :

NLT 98.00 and NMT 102.00 % (ODB)

Chromatographic conditions :

| Column | Inertsil C18, 4.6 X 250 mm, 5µm. |

| Wavelength | 219 nm |

| Flow rate | 1 ml/min |

| Mobile phase | Buffer : Methanol; 48 : 52 ( v/v). Preparation of buffer solution : 5.7 gm/lit Ammonium phosphate in water, adjust pH 6.3 with triethylamine |

| Diluent | Mobile phase |

| Injection volume | 10 µl |

Standard preparation: Dissolve and dilute 25.0 mg of Tapentadol hydrochloride sample in 50 ml of volumetric flask, make up with diluent.

Sample preparation: Dissolve and dilute 25.0 mg of Tapentadol hydrochloride sample in 50 ml of volumetric flask, make up with diluent.

Procedure:

1) Condition the HPLC column by mobile phase to obtain stable baseline (approximately 30 minutes).

2) Inject Blank followed by six replicate injections of standard solution.

3) Inject test solution in duplicate only after fulfillment of system suitability.

System suitability:

Relative standard deviation of six standard solutions should be not more than 5.0%

Order of injection:

| Blank | 1 |

| Standard solution | 6 |

| Blank | 1 |

| Test solution | 2 |

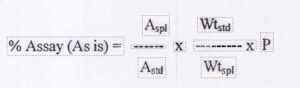

% Assay

% Assay (ODB) = ——————- X 100

(100-% LOD)

Where,

Aspl = Average area of Tapentadol Hydrochloride peak from test sample solution.

A std = Average area of Tapentadol Hydrochloride peak from six replicate injections of standard solution.

Wt std = Weight of Tapentadol Hydrochloride standard in mg.

Wt spl = Weight of Tapentadol Hydrochloride test sample in mg.

p = Purity of Tapentadol Hydrochloride standard.

LOD = Loss on drying.

ODB = On dried basis.