If you are looking SOP for Operation Calibration and Cleaning of DT Apparatus then you are landed 0n the right page. In this blog post, we are going to share the process of Operation Calibration and Cleaning of DT Apparatus. It is the unique standard operating procedure Operation Calibration and Cleaning of Disintegration Apparatus equipment. After reading this article you will be able to understand the basic concept of cleaning equipment SOPs.

PURPOSE:

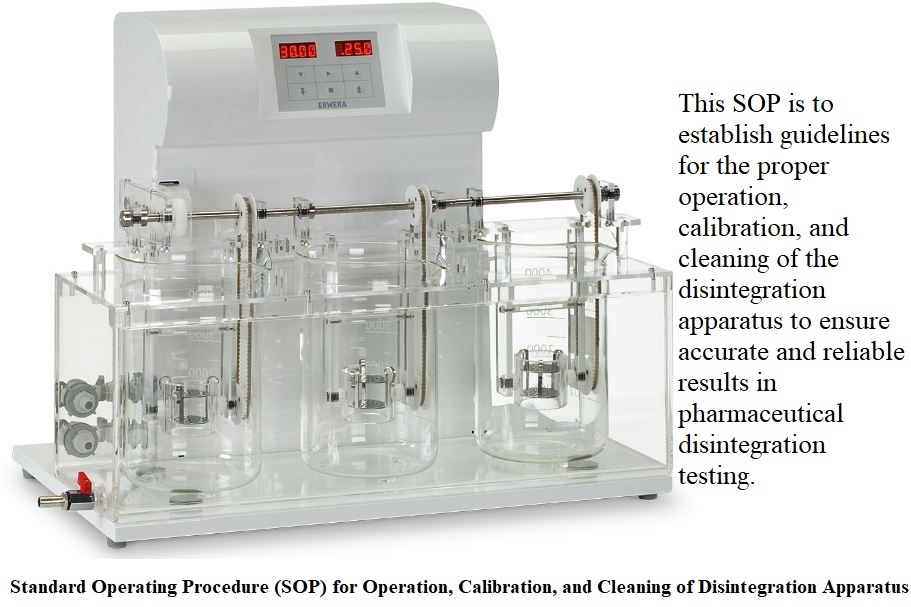

To lay down the procedure to perform the Operation, Calibration and Cleaning of DT Apparatus. This SOP is to establish guidelines for the proper operation, calibration, and cleaning of the disintegration apparatus to ensure accurate and reliable results in pharmaceutical disintegration testing.

SCOPE of SOP for Operation Calibration and Cleaning of DT Apparatus

This SOP is applicable to all DT apparatus installed in QA-IPQC-QC of egg Group of Companies.

Role & Responsibilities

| Roles | Responsibilities |

| QA Officer |

|

| Lab Attendant |

|

| QA Executive |

|

| QA Manager |

|

PROCEDURE

Startup SOP for Operation Calibration and Cleaning of DT Apparatus

- Fill the bath with water up to the level marked and check the water level in the instrument and replace the water if required.

- Fill the beakers of 1-liter capacity with approximately 800 ml water, The volume of liquid is such that the wire mesh at its highest point is at least 25 mm below the surface of the liquid and at its lower point is at least 25 mm above the bottom of the beaker.

- SOP for Operation Calibration and Cleaning of DT Apparatus

- At no time shall the top of the basket – rack assembly becomes submerged.

- Connect the basket to the basket hook.

- Switch “ON” the instrument.

- Press the Key Heater (F2) to start the heater.

Operational Procedure of Disintegration Test Apparatus:

- If the temperature of the disintegration medium reached to set temperature, then add to the samples into the basket assembly with disc or without disc, as per requirement.

- To start the test, press Start Key the particular basket assembly on which the sample is placed.

- Temperature range should be 37±2˚C.

- The time will show on the timer display.

- SOP for Operation Calibration and Cleaning of DT Apparatus

- Record the time at which all the six dosage forms (tablets or capsules) get disintegrated.

CALIBRATION FREQUENCY:

- Hygrometer should be calibrated yearly by approved external agency.

- Check and record the Temperature and Relative Humidity at about 11:30±30 minutes and 16:30±30 Minutes.

ANALYTICAL PRACTICES: DISINTEGRATION TEST APPARATUS:

- The Disintegration Test Apparatus shall consist of basket rack assembly with a 1000m1 low form beaker, for the immersion fluid, a thermostatic arrangement for heating the fluid between 35° and 39°C.

- The volume of immersion fluid in the vessel is such that at the highest point of upward stroke the wire mesh remains at least 25mm below the surface of the fluid and descends to not less than 25mm from the bottom of At no time should the top of the basket rack assembly become submerged.

- Place 1 dosage unit in each of the six tubes of the basket and, if prescribed add a disk. SOP for Operation Calibration and Cleaning of DT Apparatus Operate the apparatus using about 800m1 of the specified medium as the immersion fluid, maintained at 37 ± 2°C

- Record the time at which the last of six units have disintegrated completely.

- If at the end of the time limit specified 1 or 2 tablets fail to disintegrate completely, follow the respective pharmacopoeial criteria for a further stage, analysis.

CLEANING OF DISINTEGRATION TEST APPARATUS:

- Tube and bath: Fill half bath with 2.0 % non-ionic detergent solution (e.g. Teepol) and circulate for about 10 minutes and then with purified water. Perform the activity twice a week.

- Fill the cleaning log as per QA-F-084

- After completion of the test, clean the instrument as per the respective cleaning procedure.

PRECAUTIONS:

- Ensure that product in the respective area is in closed condition.

- Before swinging the hygrometer in the air, ensure that the hygrometer will not hit with the wall or with the nearby equipment.

- While handling it, if hygrometer is damaged inform to QA and get replaced with new calibrated hygrometer.