General SOP for Batch Processing

Standard Operating Procedure (SOP) for Review of General SOP for Batch Processing in the pharmaceutical manufacturing industry. A detailed checklist for review of General SOP for Batch Processing for Draft Copy as well as Filled Copy of Batch Manufacturing/Packing Records. this SOP is to define the procedure to review the draft General SOP for Batch Processing prior to final approval. Also, this SOP shall be applicable for a review of executed BMR prior to the final release of batches.

PURPOSE :

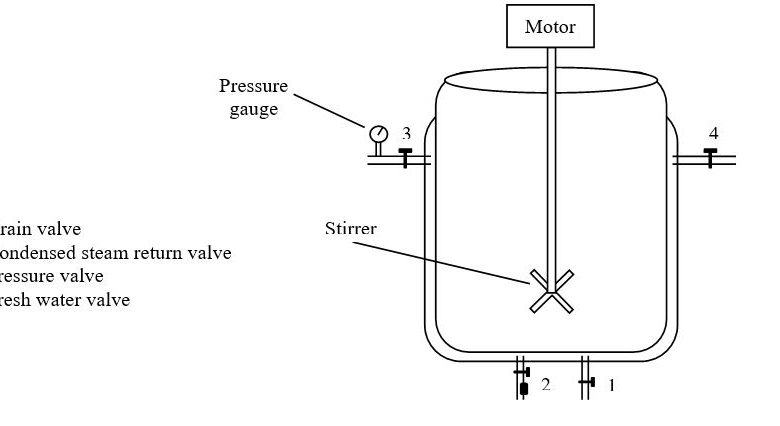

To lay down the procedure for manufacturing Tablets and Capsules.

SCOPE:

This SOP shall be applicable for Tablet & Capsule Manufacturing in the Production department.

RESPONSIBILITY:

1 Execution: Production Pharmacist.

2 Checking: Production Manager.

3 Q.A Officer.

REFERENCES:

In-hous...